DFM/A SERVICES

When a product is designed without thinking about the number of components it will have or just how challenging the manufacturing procedure will be, it is bound to fail. With a standardized DFM/A technique, the best manufacturing and assembly procedure is taken into consideration in the layout, brand-new or enhanced items can be made, made, and offered to the consumer in a shorter amount of time.

OUR DFM/A PRACTICE:

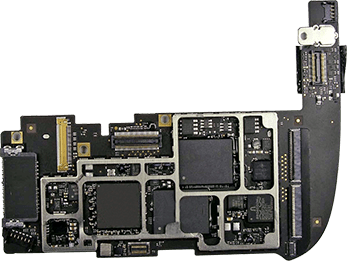

Reduce Quantity of Component Parts and Circuit Design

Design PCBs for Ease of Fabrication & Assembly

Design Within Known Process Capabilities and Avoid Tight Tolerances

Utilize Common Parts and Materials

Mistake Proof Product Design and Assembly

Handling Requirements and Part Orientation

Reduce / Eliminate Flexible Parts and Interconnections

Modular Product Design