QUALIFIED PCB MANUFACTURER

Original Material

We ensure the rights and interests of our customers, using high-quality PCB materials 100% original components to achieve the best PCBA assembly performance.

Our procurement managers have an average of 15 years of industry procurement experience, provide BOM analysis, select components for you based on a wide range of channels, all components are subject to third-party inspection. Meanwhile, PCBANow adopts an advanced warehouse management system (temperature, humidity, anti-static) to protect materials from aging.

●100% Original Components

●Branded Solder Paste & Flux

●Advanced Warehouse Management

Promise High Quality PCB Assembly

1. Project progress deduction, NPI trial production follow-up.

2. DMFA & engineering data convert and formulate guideline documents.

3. The 11 high-end production lines are uniformly equipped with SPI to ensure that the SMT process solder paste meets industrial-grade standards.

4. In the patch of components, choose brand solder paste to ensure the reliability of soldering.

5. Cooperating with automatic printing machine, SPI, imported automatic high-speed placement machine, 12 temperature zone reflow soldering, AOI machines, offline optical detector, X-ray machines, etc., can effectively ensure stable and reliable quality during the process of soldering.

6. Complete IPC, IPQC, QA, QC management, clear job responsibilities, and strict implementation of IPC assembly acceptance standards.

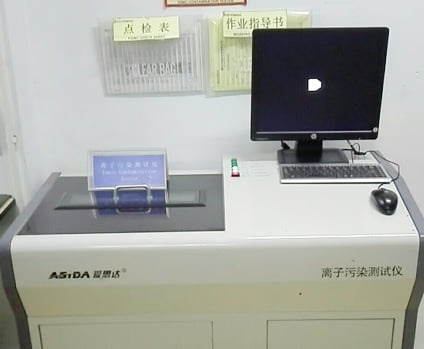

7. Regarding PCBA testing, we have professional engineers who use various test racks to conduct 100% batch testing, including path, noise, amplitude, signal, temperature, humidity, drop or execute customer's detailed test plan.

8. Pay attention to the feedback of customers, and make a QCC improvement plan around the feedback.

Reliable Testing

An effective Quality Assurance program, integrated throughout the assembly process, is vital as PCB designs become increasingly more complex with smaller layouts. The quality system for our PCB Assembly services is registered to ISO 9001:2016 and includes the following facets:

AFTER-SALES SERVIES

- We will follow all tracking information after shipping until all products arrive customer's hand.

- We will give a reaction and the best solution within 24 hours after receiving the customer's claim.

- If the customer proves our quality issue and we will undertake all costs.

- We offer several free sample chances for our VIP customers.